United Pharmatek's Compact High Speed Press Pill Press Tablet

Press Machine can produce up to 185,000 tablets. Color touch

screen 7”, with display of main average pressure, single punch

pressure, alarm at fault, automatic stop and help menu. Three

handwheels are used for adjusting main compression (tablet

thickness), pre-compression, and filling. Hydraulic support

adjustable for main compression and pre-compression.

Auto-pressure keeping and pressure overload protection.

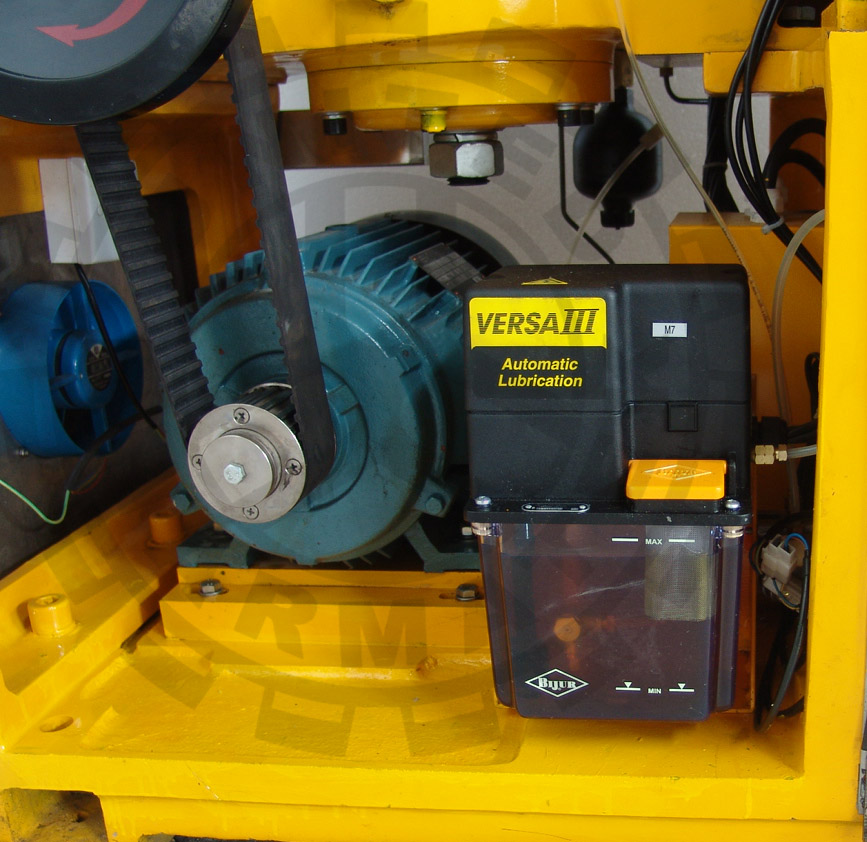

Automatic Lubrication system. Lubrication flow rate and interval

can be adjusted. Under lube alarm, lubrication pressure fault

alarm and auto-stop protection. Grease lubrication system

controlled manually

New technological improvements deliver high quality tablets with

accurate weights, lower waste, and efficient operation for the

pharmaceutical industry. All parts are constructed with high

quality stainless steel to meet the GMP Standard in the

industry. The punches and dies are IPT and EU international

standards. The main mechanical components of the machine have

built-in safety features to protect the punches, dies and

turret.

It has the security access management function in accordance

with FDA 21 CFR Part 11. The touch screen has three levels of

user rights management functions, and different rights

correspond to different operation levels. It has the data

recording function in accordance with FDA 21 CFR Part 11. It can

save, call and record the production parameter formula, and also

record the production data and alarm information. The recorded

data is saved on SD card in RDB or CSV format. It has the audit

trail record function in accordance with FDA 21 CFR Part 11. It

can automatically record the user login / logout, main button

operation and parameter modification of the system. The recorded

data includes time stamp, user name and event description, which

are saved on SD card in RDB or CSV format. Audit trail record,

and you can also choose to a virtual printing documents as PDF

format on the touch screen. Program backup / recovery function.

Touch screen and PLC applications can be backed up and restored

by SD card