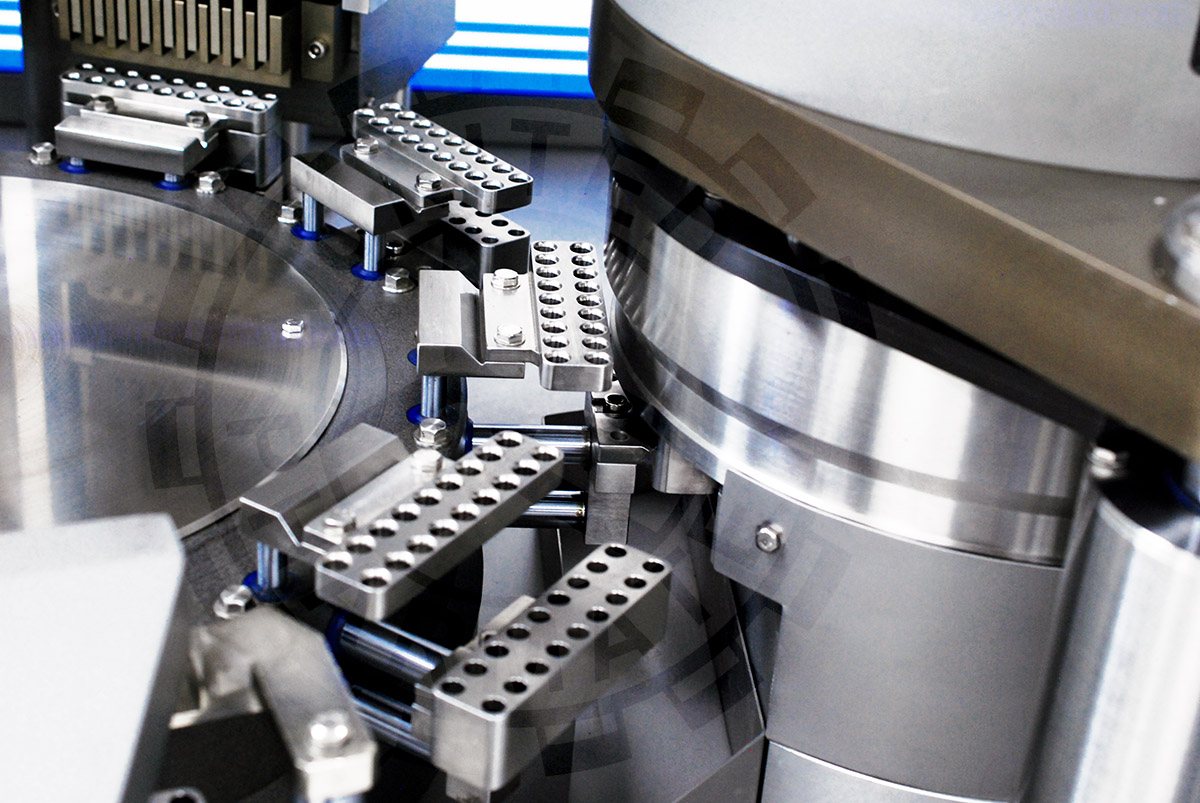

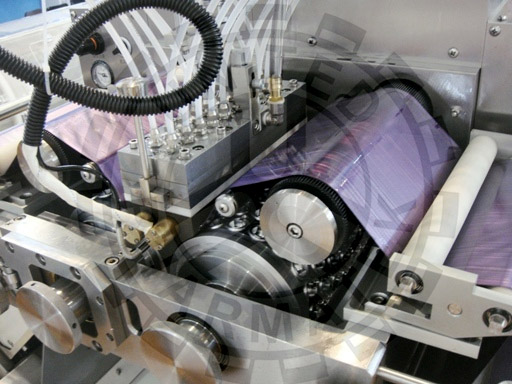

A Capsule Machine, Capsule filler, capsule filling machines, also called Encapsulators or encapsulation machines are machines commonly used in the pharmaceutical, nutraceutical industries to fill empty soft or hard gelatin capsules of various sizes with powders, granules, semi-solids or liquid substances containing active pharmaceutical ingredients or a mixture of active drug substances and excipients. This process of filling empty capsules with substances is termed encapsulation.

Capsule Filling Machines can be classified as two types.

- Hard Gelatin Capsule Fillers

- Soft Gelatin Capsule Encapsulators

Our machines are specially designed to meet your unique production requirements from a Semi automatic capsule machine to fully automatic high speed production. United Pharmatek's capsule fillers incorporate the best technology to help you successfully and easily dispense accurate dosages for every capsule produced.