- Home

-

Equipment

- Automatic Tablet Counter

- Blenders

- Blister Packaging Equipment

- Bottle Labeler

- Capsule Filling Machine

- Capsule Polisher

- Capsule Separator

- Comill

- Film Coating Machines

- Fluid Bed Dryer

- Granulator

- Inspection Machine

- Lab Equipment

- Liquid Filling Machine

- Material Handling

- Packaging Equipment

- Softgel Encapsulation Machine

- Tablet & Capsule Printer

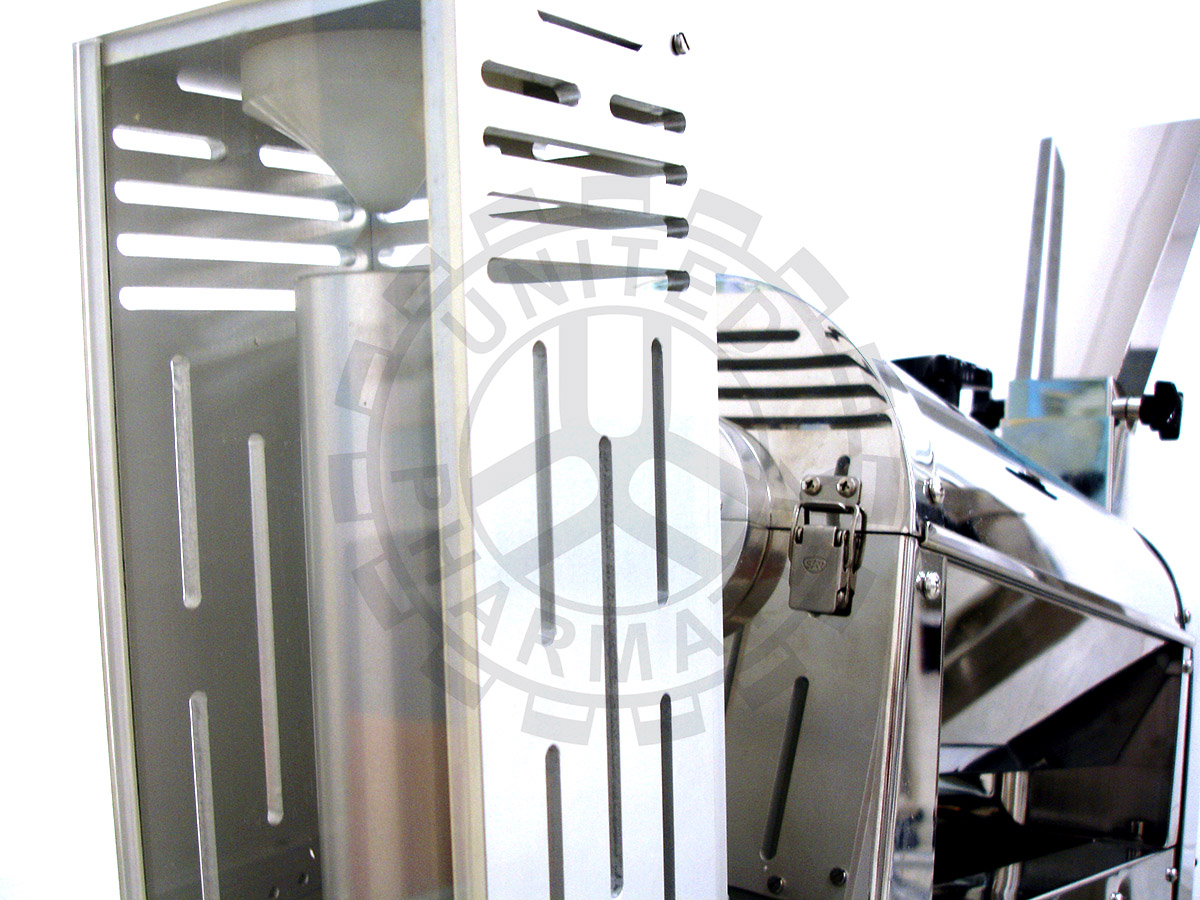

- Tablet Deduster

- Tablet Press Machine

- Tube Filling Machine

- Financing

- Contact