United Pharmatek provides a wide range of lab equipment for every quality control process in pharmaceutical testing that meet USP Standards. The testing specifications established for tablets include physical, chemical and biological tests. Physical testing specifications can comprise of size, shape, color, friability, breaking force or hardness, and disintegration.

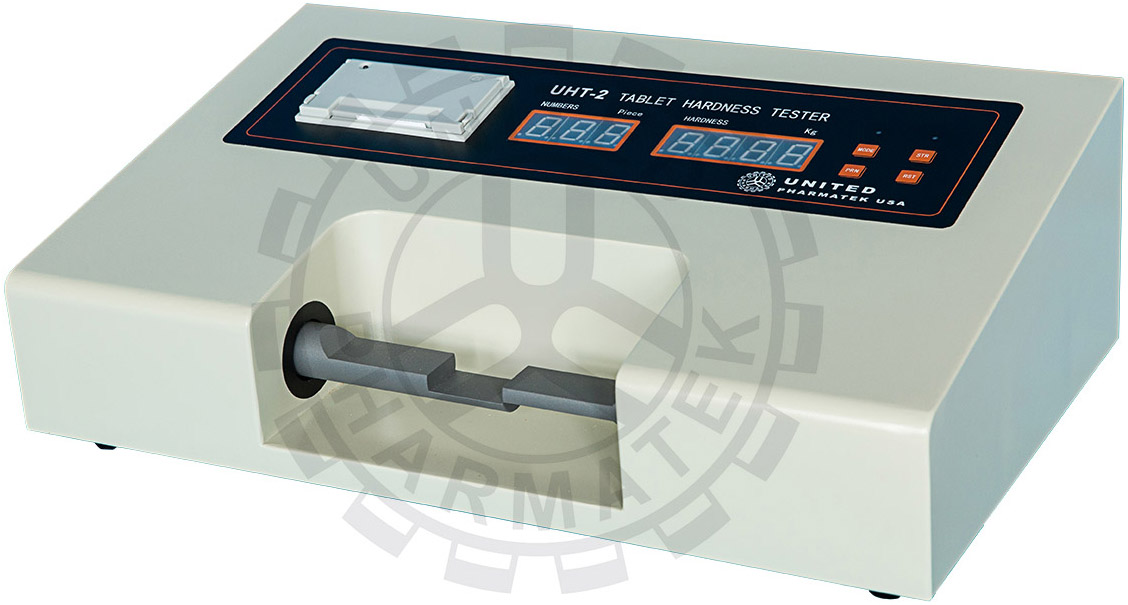

Our Tablet Hardness Testers are used in the pharmaceutical industry to test the breaking point or "Tablet Break Force" (the force required to cause them to fail) and structural integrity of a tablet.

Our Dissolution testers are capable of performing standalone testing. The DT series can be equipped with 6 or 8 vessels. The 2 additional vessels can be used for blank, standard or media replacement. The unit consist of control system, electric system, water bath system, transmission system, lifting system, transducer unit, paddle unit and rotating basket unit, etc.

Our Disintegration Testers test whether tablets or capsules disintegrate within a defined period of time when placed in a liquid medium. All of our lab instruments are designed and manufactured in accordance with USP Disintegration Specifications <701> and as optional <2040>. Our UDT Disintegration Tester comes with 1 to 3 individually controlled test stations, with their own keypad for easy setting of the required run time, independent of each other.

Our Friability testers measure the potential percent of weight loss of compressed tablets by replicating the rigorous environmental conditions that tablets are subjected to during the manufacturing, packaging, and distribution processes.