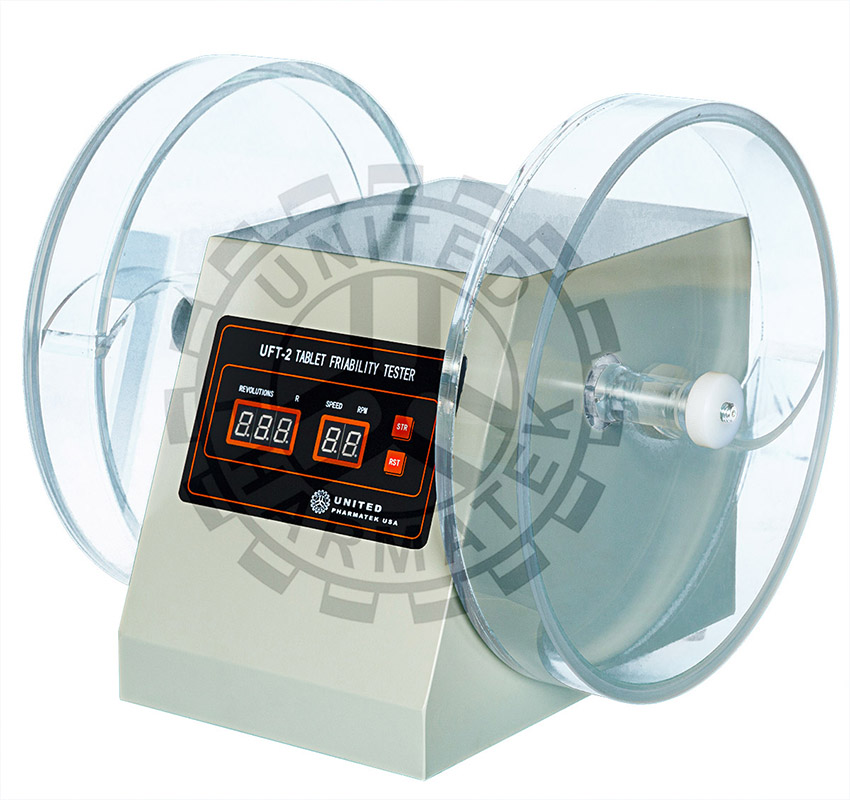

Our UFT Series Tablet Friability Tester is the requisite

instrument in detecting dissolution of tablets, capsules, etc.

All of our lab instruments are designed and manufactured in

accordance with USP specifications. The UFT-2 Friability Tester

is comprised of dual drums rotated at a fixed speed of 25 rpm.

Alternatively, the UFT-1 has variable speed from 20 ~ 90 RPM.

The standard friability drum has an inside diameter of 286 mm

and a depth of 39 mm and is fitted with a curved baffle which

subjects the tablets to be tested to a drop of 156 mm.

Tablet Friability Test Procedure

Friability Testing measures the potential percent weight loss

of compressed tablets by replicating the rigorous

environmental conditions that tablets are subjected to during

the manufacturing, packaging, and distribution processes.

Tablets need to be hard enough not to break up in the bottle

but friable enough that they disintegrate in the

gastrointestinal tract.

In a friability test, samples are counted and weighed, then

tumbled in the rotating drums with baffles. Friability is

determined when the process is stopped by weighing the samples

again and calculating the difference between the before and

after weight. Friability should not exceed 1%, which is

considered the ideal percentage.