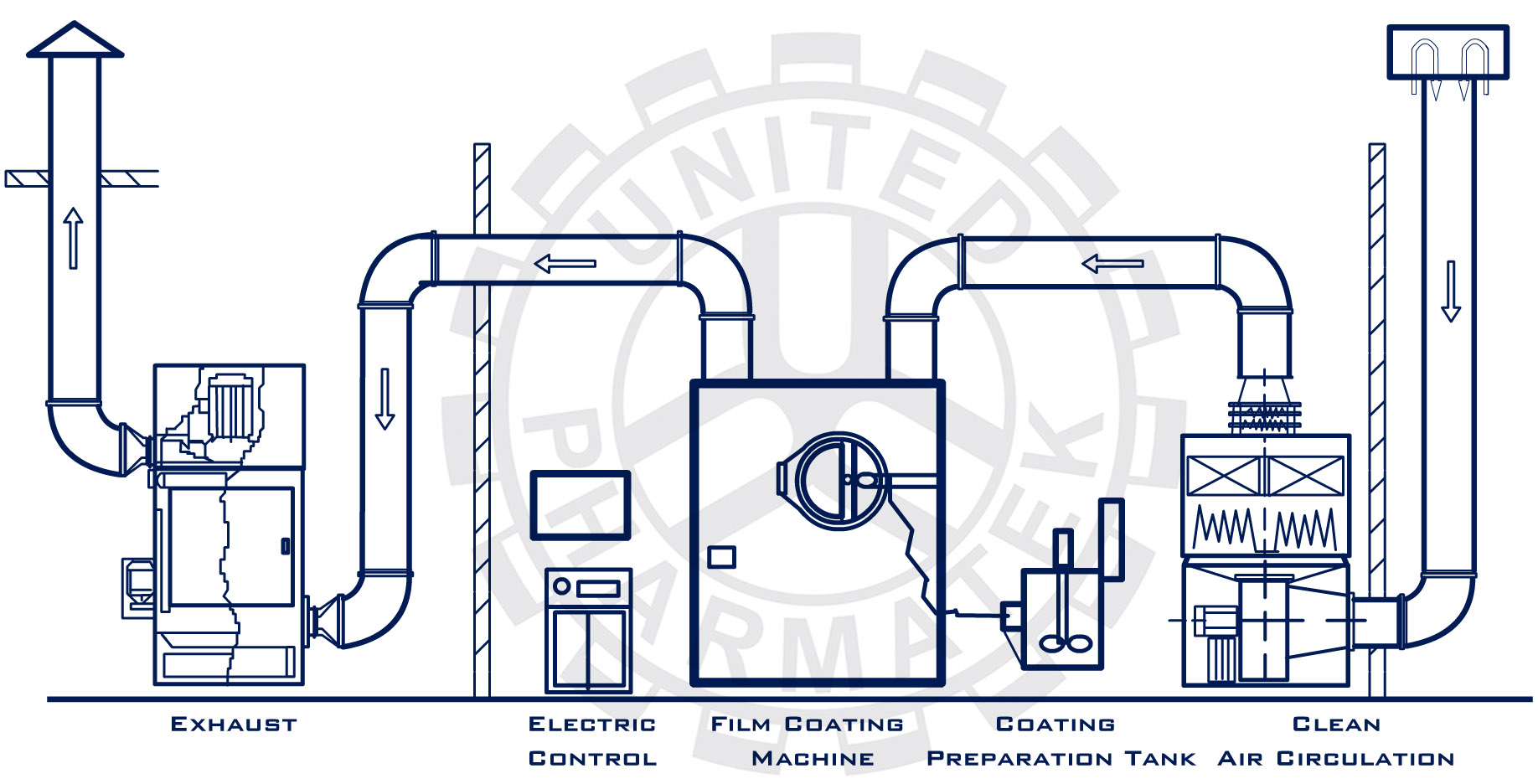

Model FCS Series Advanced Film Coating Machines are widely used

in pharmaceutical, nutraceutical, herbal, chemical, food and

confectionary industries. This machine features high quality,

advanced design and is manufactured in conformance to the cGMP

standard. United Pharmatek's film coating machines are ideal

equipment for coating tablets, pills, capsules or candies with

organic film, water-soluble film, slow and controlled release

film, and sugar film. We have state-of-the-art technology to

solve issues arising from difficult to coat products. They are

high-efficiency, energy saving, and easy to clean, with minimal

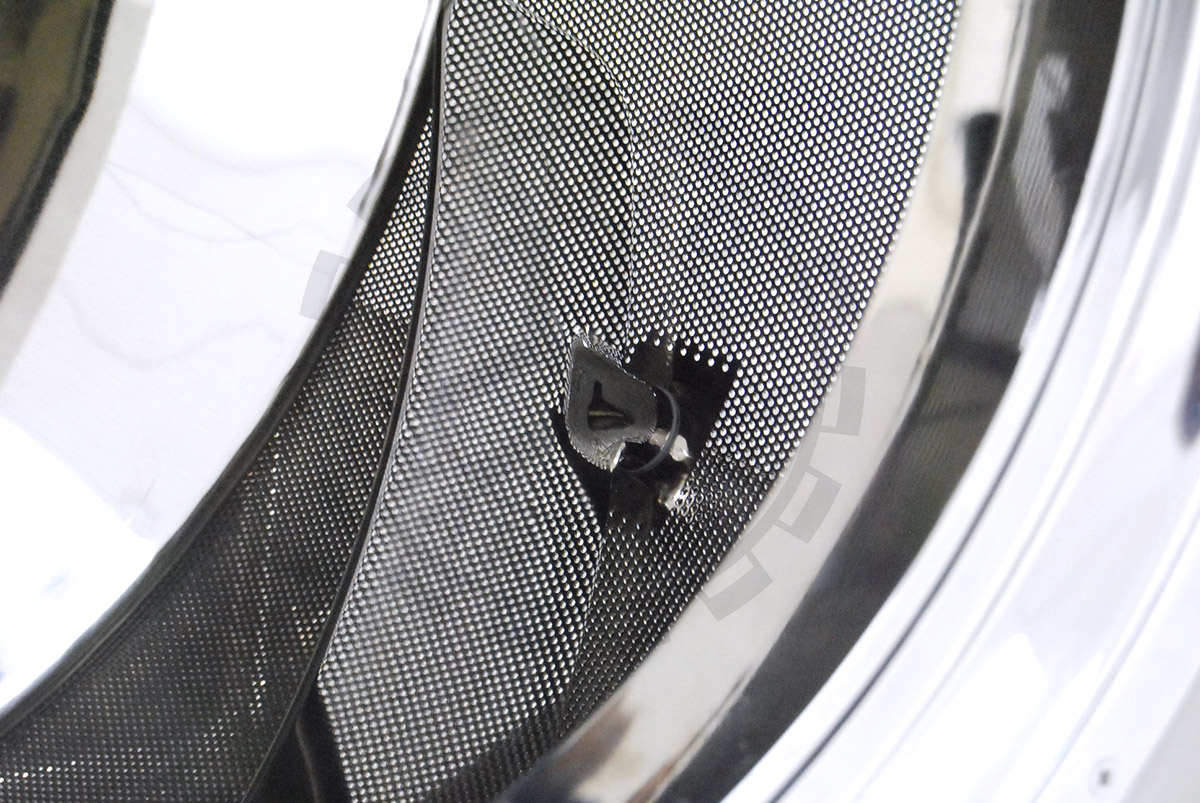

waste material. Tablet coating machines work on the simple

principle of applying the coating solution through a set of

spray guns on a group of tablets inside the coating pan in a bed

that may move horizontally or vertically. A concurrent flow of

heated air helps to evaporate and dry the coating solution. The

coating is equally distributed to the tablets through the

rotation of the pan. The rotating motion causes the tablets to

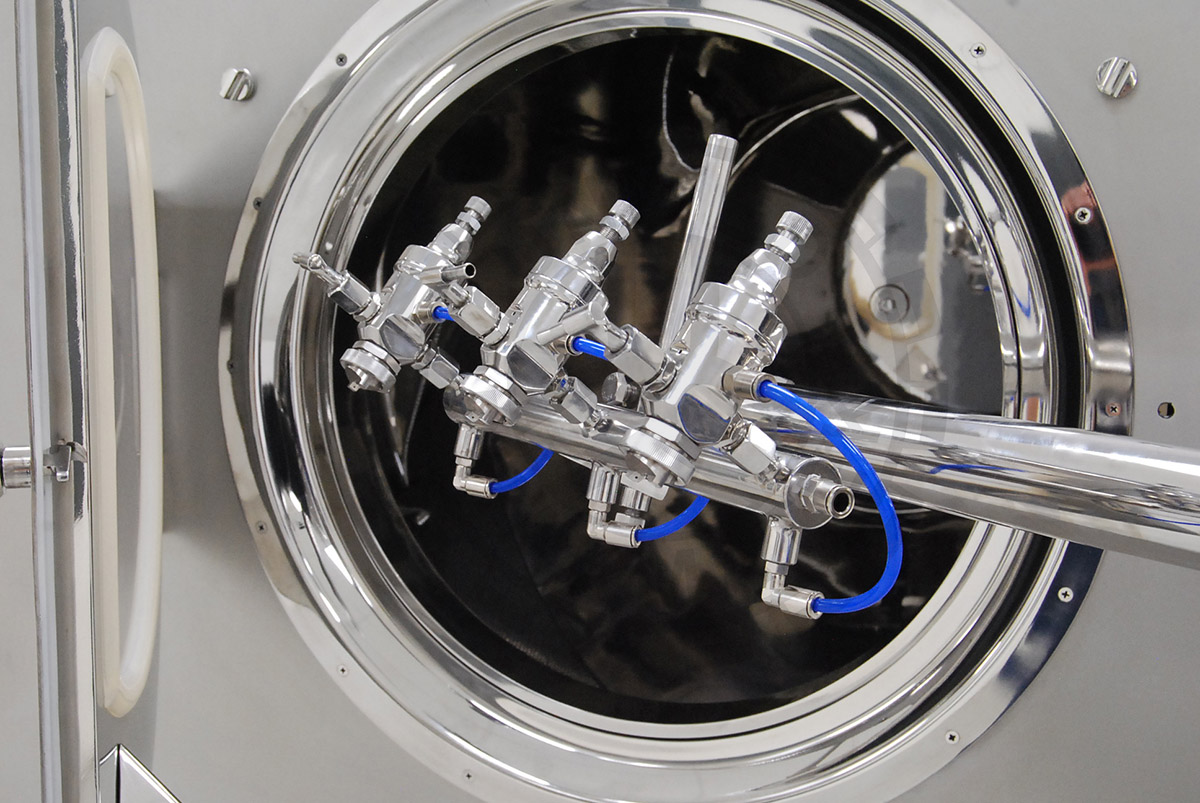

tumble within the pan. Coating solution is applied to the

rotating tablet bed by spraying it in atomized form, which

provides a faster and more even distribution. Spraying nozzles

are positioned inside the drum to evenly coat the tablets as

they are tumbling inside

All of the operations of the film coating machines, including

expansion of PLC modules, setting and control of hot air

temperature, and adjustment of drum speed, are controlled by

SIEMENS HMI (Human

Machine Interface) with

SIEMENS Color Touch

Screen Panel. The operating panel is a fully enclosed, light

touch film interface, which does not influence the cleaning of

the main machine. This ensures reliable operating, stable

performance and conforming to the requirement of cGMP. Model FCS

is made with high quality

SIEMENS electrical

components.