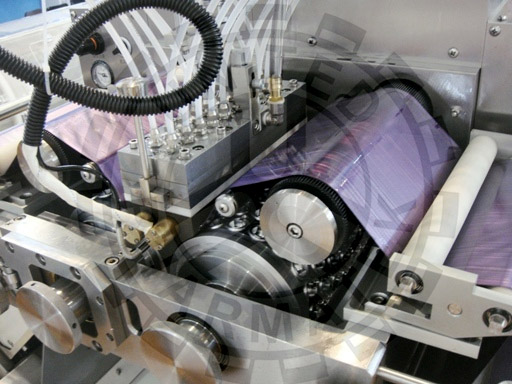

Softgel Machine Tooling Dies

Complete Set of Die Roll Set included

Complete set includes, 2 die rolls with stainless steel

inserts, aluminum wedge, distribution plate, Timing gear.

200L Gelatin Service Tank

Inner and outer mirror polished finish (Water Heated)

SUS 304, triple layer. Equipped with Air Pressure Meter,

Temperature Meter, Light, Heat Preservation Valve and

Observing Window .

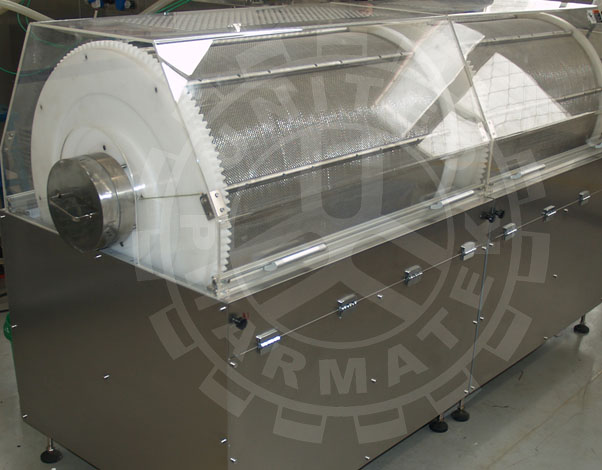

Large Tumble Dryer Included

Adjustable Speed of Tumbler Dryer: 0~30 rpm adjustable

Each Basket Tumbling Dryer Size: Ø4100x880x1200mm