United Pharmatek's Tablet Presses finished product output

can range from 100,000 Tablets per hour up to 528,000 per hour.

Each Automatic Rotary Tablet Presses are widely used in the

pharmaceutical, herbal, nutraceutical, chemical and food

industries to produce all types of round tablets and other

irregular shapes tablets.

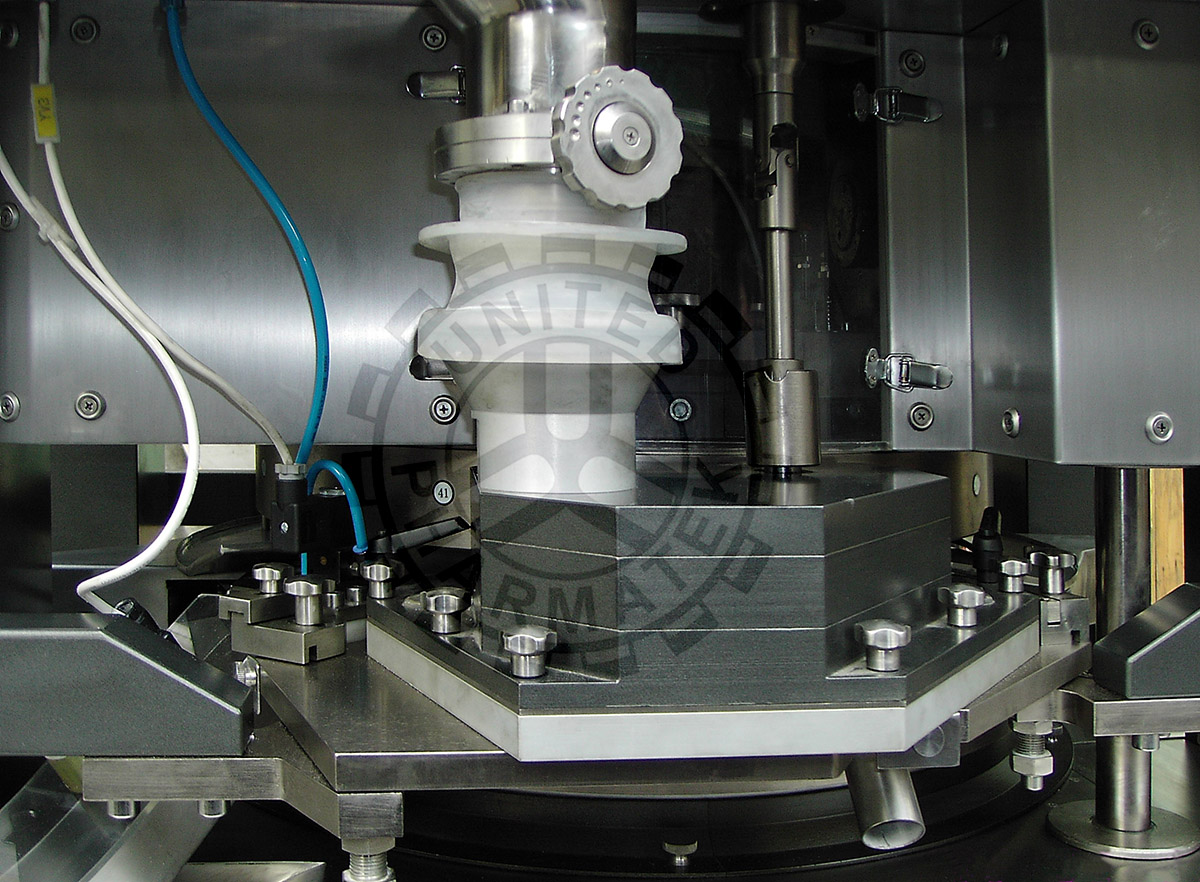

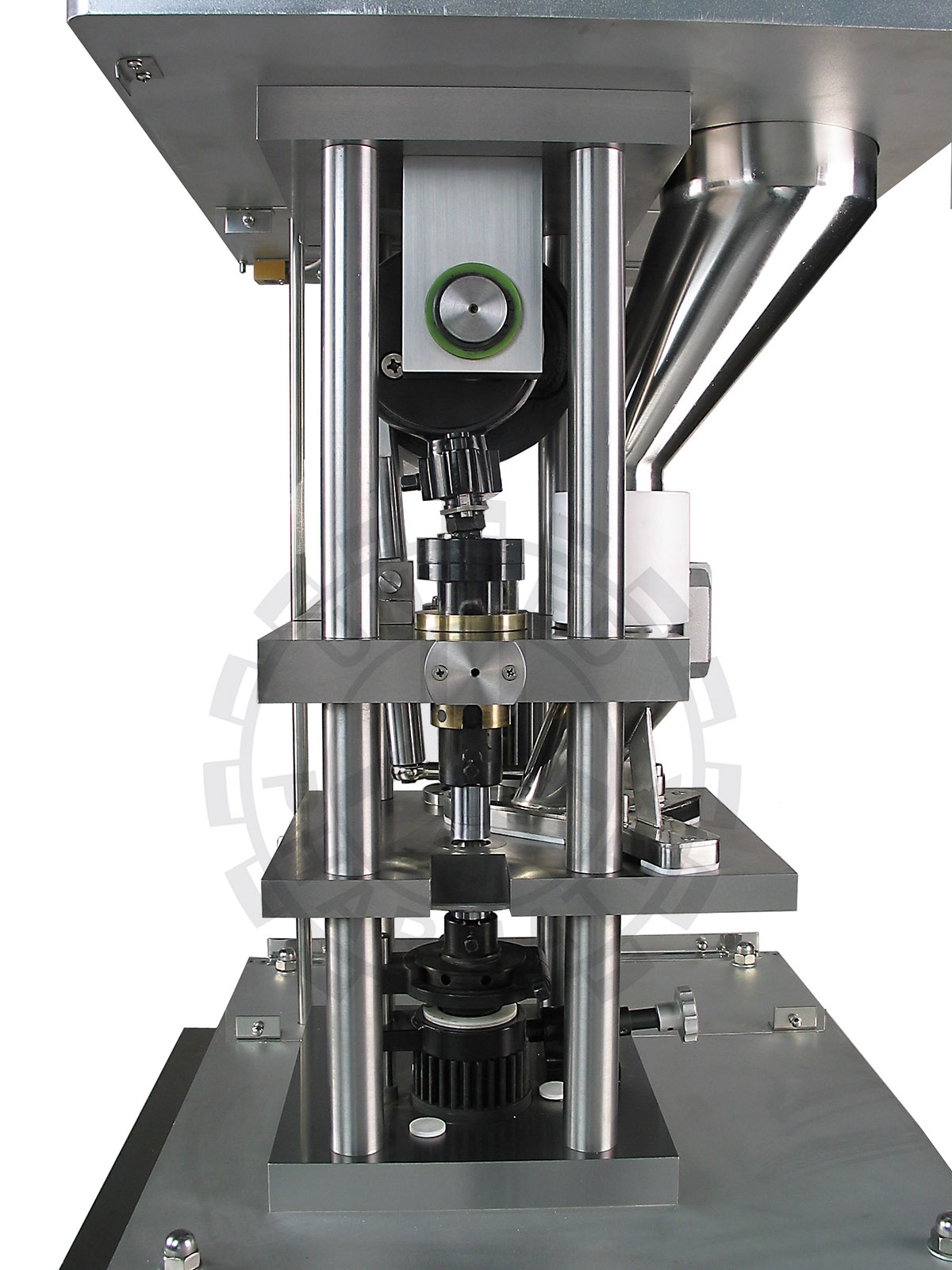

Each series of tablet presses are available in the

different types of tooling, (Type "B", "D" or "BB"). The

pressing chamber is separated from the gear driven system. The

parts in contact with tablets are made of stainless steel or the

surface of those parts are polished and sterilized. The chamber

is also sealed with organic glass for a better working

environment. The gear system, the cams and the major friction

parts are fully lubricated by the continual and concentrated

lubrication devices.