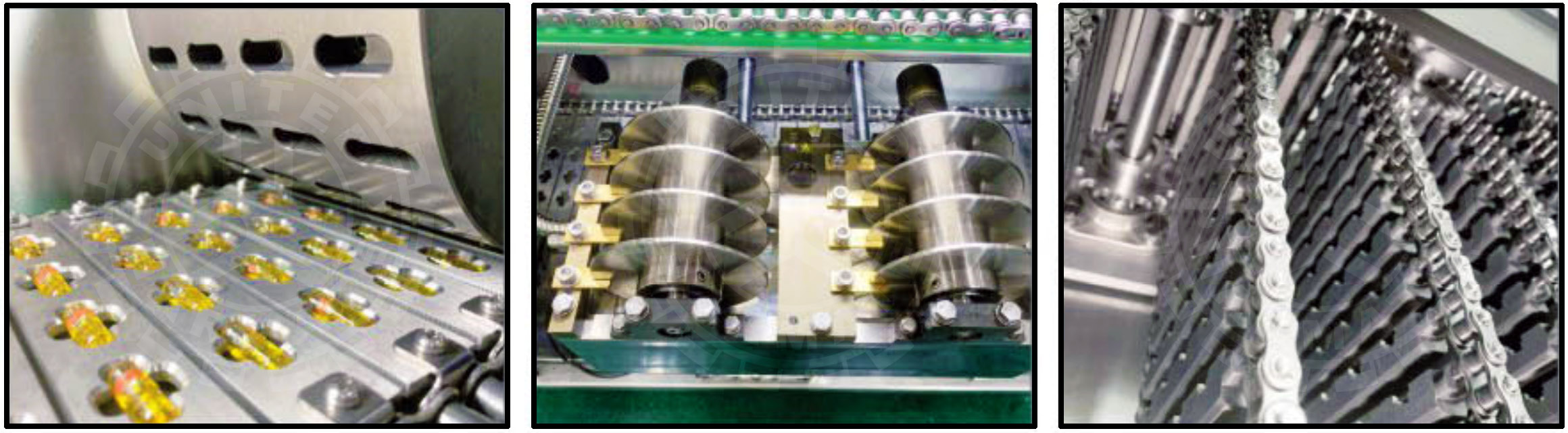

Our mid-speed automatic capsule filling machine is designed to fill hard gelatin capsules with Oil based solutions and suspensions. These machines are durable and reliable for filling empty gelatin capsule dosages to the highest accuracy. The operation of this fully automatic capsule filling machine is very smooth, simple to operate, and easy to maintain and clean, with low noise. These capsule fillers are built to meet the world's most advanced hard shell capsule encapsulating production requirements. Our capsule fillers will work with hard gelatin capsules in sizes 00, 00, 0, 1, & 2. All parts are made of high quality stainless steel to meet the cGMP standard. We integrated only SIEMENS electrical components and SIEMENS PLC for reliability.

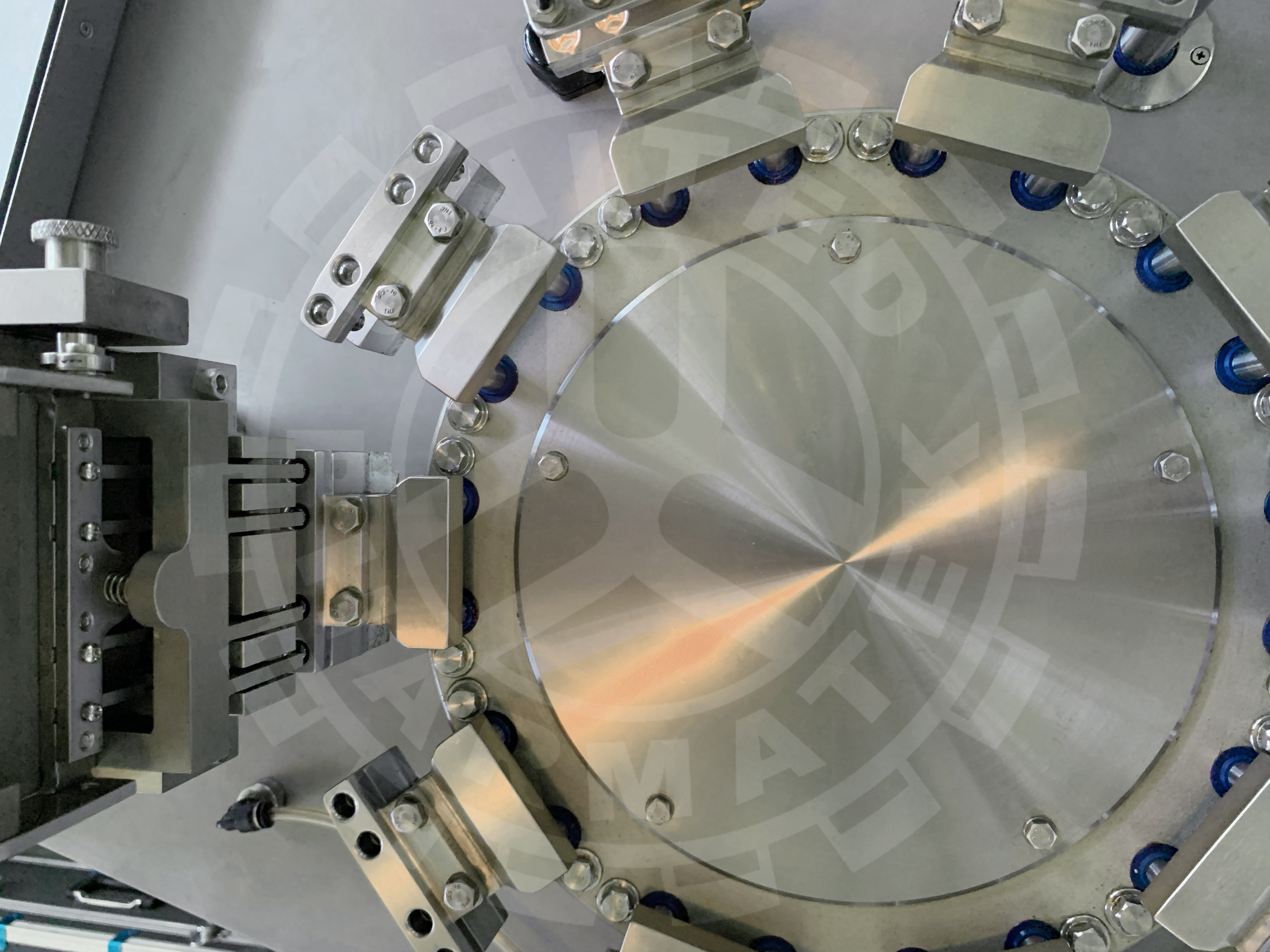

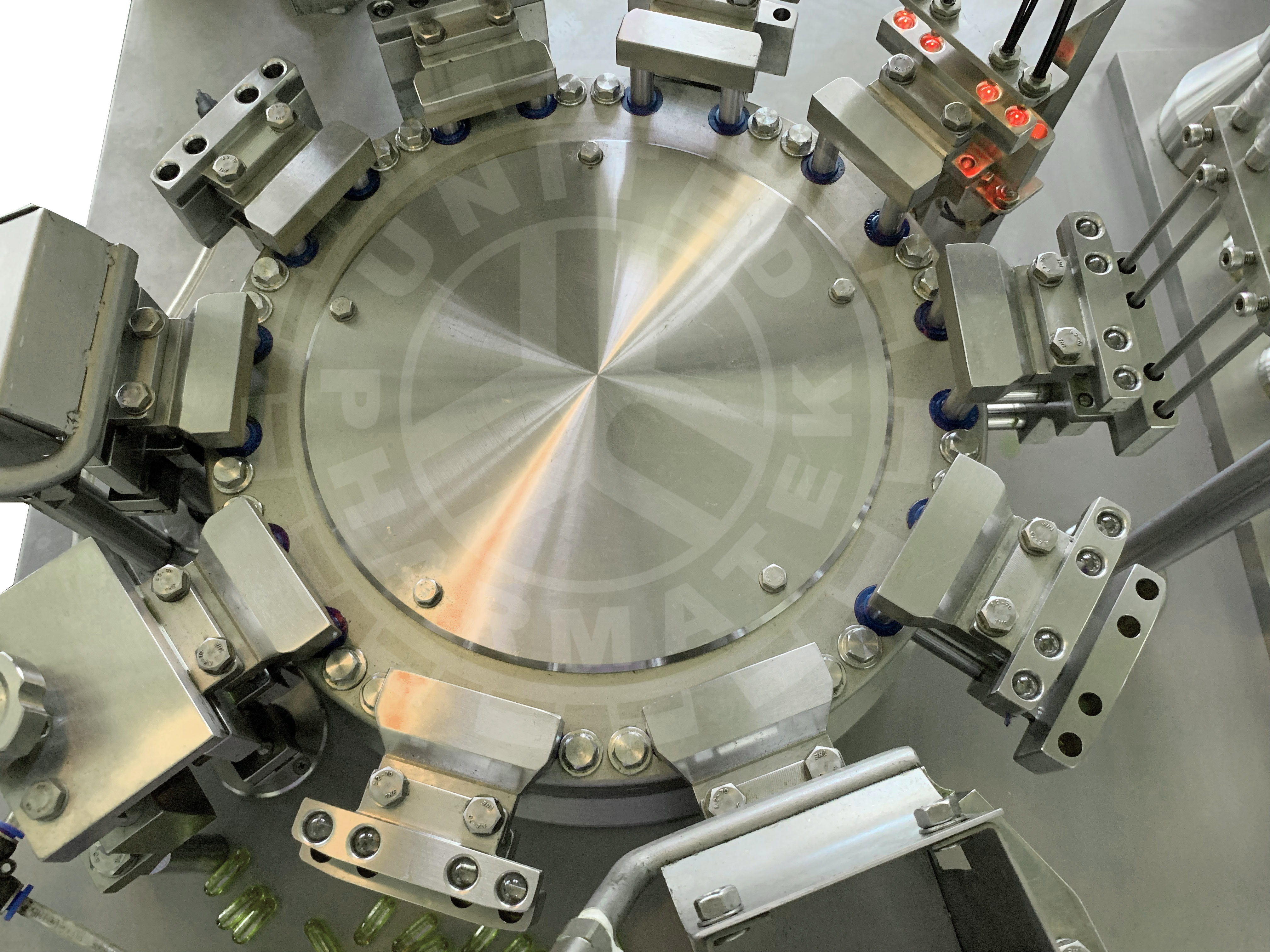

United Pharmatek's Mid Speed Capsule Filler Machine has a finished product output range up to 36,000 capsules per hour on our Model UAF-600L or 27,000 Capsules per hour on our Model UAF-450L and 18,000 Capsules per hour on our Model UAF-300L. Each capsule filler is designed to increase production rates and decrease the time required to get product to market. With its high filling rates and full automation of the capsule filling process, United Pharmatek's capsule fillers allow for minimal operator training, lower productions costs, and reduced wastage. Quick change over time offers the customer the ability to run many products or one product continuously, making them suitable for all types of manufacturers in the pharmaceutical, nutritional, foodstuffs and chemical industries who require a low maintenance, large scale production capacity. The enclosed turret design makes for simple clean up and maintenance.

Each capsule filler automatically orientates, opens the empty hard gelatin capsule, properly fills the capsule with liquid. The capsule filling machine includes sensors for both product hopper and empty capsule hopper to ensure continuous uninterrupted operation. Defective capsules, such as unseparated capsules, are automatically ejected during the operation through vacuum suction. Air blow-out pins clean the segments after the capsules have been ejected and the complete capsule filling process is repeated for a fully automatic operation. .