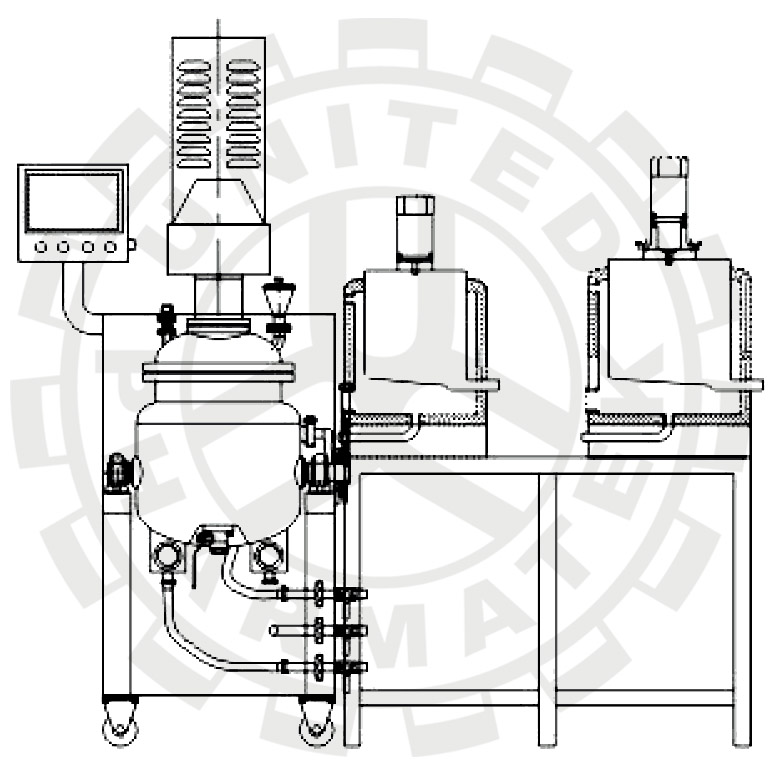

Model URJ Vacuum Emulsification Mixers are specially designed

for processing cosmetics and ointments. They are composed of a

pretreatment Jacketed Oil or/and Water Tanks, vacuum emulsifying

mixer (Jacketed), vacuum pump, hydraulic system, tilting

discharge system, and electric control system.

Structure:

With 3-layer structure, upper and lower end sockets. The upper

end socket is connected to the tank body with flange between

them. The internal layer of tank body is made of 5 mm thick

SUS316L stainless steel and interior polished in 400 MESH

(sanitary level). The middle layer of tank body is made of 4mm

thick SUS304 stainless steel and can stand max. Working pressure

is 0.09 MPa(coil tube). The external layer of tank body is made

of 2 mm thick SUS304, and exterior polished in 300 MESH

(sanitary level). All the welding seams shall be polished after

rubdown, and as to the treatment interface, turned over edge arc

transition is adopted. The heat preservation layer is made of PU

polyurethane foaming.