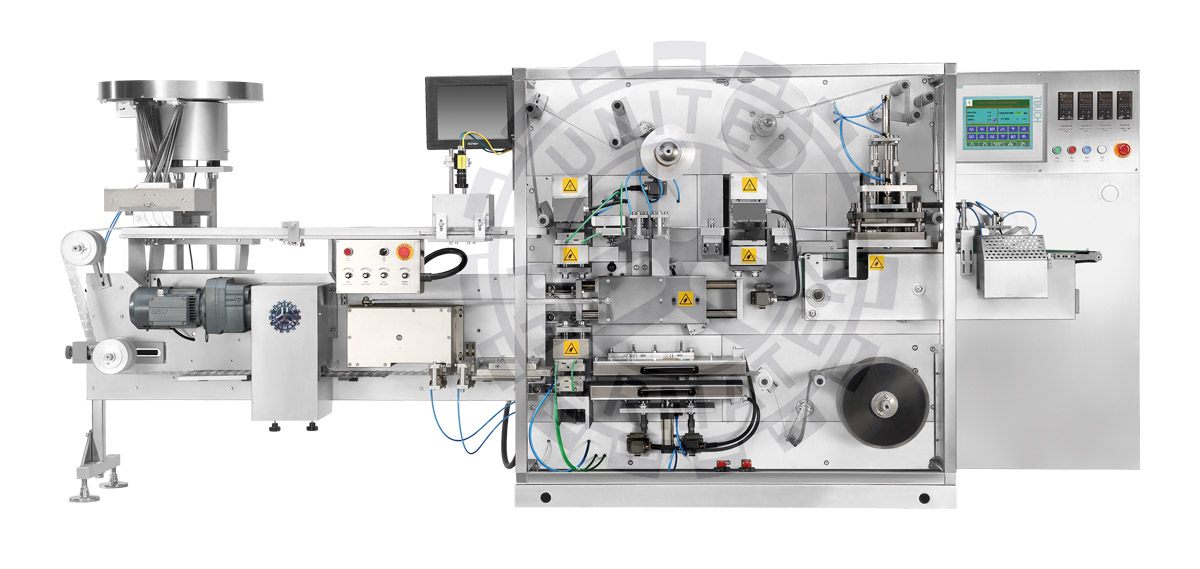

Our model UBM-170 Blister Packaging Machine is mid-speed production blister packaging equipment designed to pack all types of capsules, tablets, softgels, and injection solution into blister packs. It is suitable for packing Alu - PVC blister packs with an option for Alu/Alu foil blister packs. United Pharmatek delivers world-class quality, reliability, and performance for a blister pack machine that is cost effective. This machine is ideal for pharmaceutical and nutraceutical industries.

The spaces between the forming, heat sealing and cutting parts can be adjusted as required. It is excellent for packing tablets or capsules of various sizes with high precision and efficiency. It is drawn by a mechanical hand with an adjustable stroke, for easy and reliable operation. Through the various mechanical movements, a blister packaging machine forms cavities on the PVC, fills the cavities and then seals the blister pack with the aluminum foil. This results in a finished blister pack that protects products and is free of moisture/humidity, light, oxygen, etc., depending on the type of blister pack material. Blister packaging is the best option to tamper proof your product, when compared to bottle packaging. This is because the only way to access the product is by tearing or opening the blister pack.

Features:

- The machine adopts modular design. Each station can work individually.

- SIEMENS Color Touch Screen Control Technology

- SIEMENS PLC Control System

- Easy format parts changeover and maintenance.

- Detection system guarantees the blister pack's quality.

- The machine meets cGMP standards.

- Rugged design, durable, easy to operate for simple maintenance.